News

- 2014-08-18 16:03:39

-

How to select a VCR ZnO Varistor?

For most applications, the selection has 6 processes:

- Normal operating conditions of the varistor.

Varistor voltage: the voltage value under 1mA constant current test.

Select the ZnO with higher voltage.

A.C. / D.C.: max.rms.or DC voltage. Select the max. voltage equal or higher than the peak working voltage.-

The transient energy absorbed by the ZnO.

To determine the energy absorbed in the ZnO, the following equation can apply:

E=K×IP×Vc×T

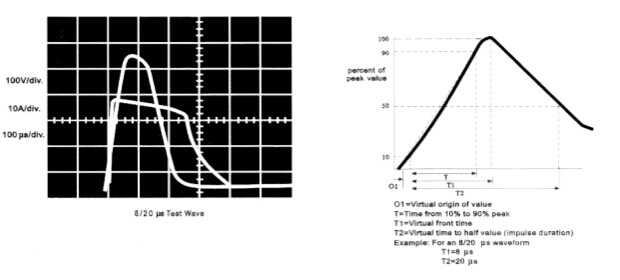

Where K is a constant. K value are 1.0 for a rectangular waveform, 1.4 for a 10/1000μs and 8/20μs waveform. And IP is the peak current applied, VC is the clamping voltage which was current applied. T is the pulse width.

It must note one thing that the rated energy and the energy absorbed in a Varistor may not be identical. It has a situation that a ZnO varistor with better clamping voltage will absorb less energy. It is very important to emphasize that poorer ZnO varistor will absorb higher energy in the ZnO varistor itself and the better ZnO varistor which performs a lower clamping voltage will absorb less energy, yet actually provides a better over-voltage protection.

Max. transient voltage that the equipment to be protected can withstand.

Select lower clamping voltage than the equipment can endure. It is easy to find ZnO varistor clamping voltage from V-I curve when the transient current is known.- Max. peak transient current that the varistor can withstand. The peak transient current can be measured in the circuit. If the transient is generated by an inductor, the peak current will not be more than the inductor change current. When the transient voltage and the circuit line impedance is known, the transient current can get by using a graphical analysis.

- Number of transient currents expected surge during life evaluates the total transient numbers in the circuit and the max. Peak current then selects the suitable model ZnO varistor that can endure.

-

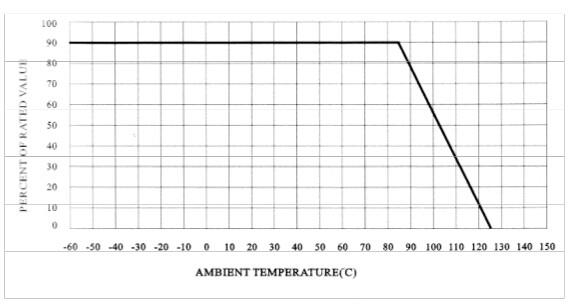

Determine power dissipation requirements. If the transients generate heat in a ZnO Varistor too quickly, it can not be transferred during the pulse interval and will cause the ZnO varistor fail. Under this condition, the power dissipation so developed must be within the specifications shown on the ratings tables. It is to be noted that ZnO varistor can only dissipate a repetitive applications that involve substantial amounts average energy dissipation.

Furthermore, the operating values will be decreased at high temperature as shown in the following figure.

- Previous [Return Home] [Print] [Go Back] Next

Contact Us

Contact Person:

Miss Li MeizhenTel:

86-769-82825339- 82825369

- 18929453899

Fax:

86-769-82829959Email:

nanalee.mc@163.com