News

- 2014-08-18 15:41:29

-

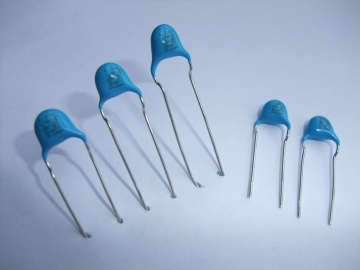

Safety Capacitors

Types of Safety Capacitors:

•There are two major types of interference-suppression/AC line filter safety capacitors; namely, type X and type Y. The purpose of these capacitors is to reduce radio frequency interference and to ensure safety from shock and fire.

•In addition to helping to block out noise interference from being received, they are also used in electrical devices and appliances to help prevent noise interference from being sent out. Below is a schematic of a modern day “line filter circuit” which shows the safety capacitor(s) C1 and C2. Capacitor C1 would be a type X “across the line” capacitor and the two C2s would be type Y “line to ground” safety capacitors.tem

•Class X capacitors are used in “across-the-line” applications where their failure would not lead to electric shock. Class X safety caps are used between the “live” wires carrying the incoming AC current. In this position, a capacitor failure should not cause any electrical shock hazards, rather, a capacitor failure “between-the-lines” would usually cause a fuse or circuit breaker to open.

•Class Y capacitors are used in “line-to-ground” (line bypass) applications where their failure could lead to electric shock if a proper ground connection were lost. The failure of a “line-to-ground” capacitor would not open any safety fuse. In other words, the failure of a line bypass capacitor could create a 120 volt “hot” chassis that could give you a potentially fatal shock.

•Because the terms X and Y are pretty non-descript, it can be hard to remember which type go where. To remember, just think of the X as being A CROSS on a 45 degree angle, and there you have it ….X is for “A CROSS the line” applications.

•Most safety capacitors have voltage ratings of 250 VAC and can be used in circuits up to 250 VAC.

Classes of Safety Capacitors:

•Safety capacitors are grouped into a number of different classes. For X Type capacitors there are class X1, X2 and X3. For Y Type capacitors there is class Y1, Y2, Y3 and Y4.

•The only types you will probably see for sale are X1 (impulse tested to 4000 Volts), X2 (tested to 2500 V), Y1 (tested to 8000 V) and Y2 (tested to 5000 V).

•Of the above capacitors, type X2 and Y2 are the most popular and the type that you will probably want to use. X2 and Y2 safety capacitors are used in appliances that plug into ordinary household wall outlets, while type X1 and Y1 are for heavy duty industrial use. For example, a type X1 capacitor would be used in an industrial computer or industrial lighting ballast that is connected to a 3-phase line (the main power truck lines within a building).

•You could use type X1 and Y1 in your tube electronics if you wanted to, but all you require to meet safety standards is the X2 and Y2. The type 1’s will cost you more money and may be more difficult to install due to their larger size.

•Are X2 and Y2 capacitors interchangeable? Yes and no! You can safely use an Y2 capacitor in place of an X2 capacitor for an “across-the line” application, but you should not use an X2 capacitor in place of an Y2 capacitor for a “line to ground” application. The X2 type would work and remove noise interference, but would not meet line-to-ground safety standards. This is because Y2 capacitors are more robust, take higher test voltages and are designed to open, (rather than short) should a failure occur.

•What do Y2 safety capacitors have in common with your cars windshield? They are both built “not to break” and if they do break, they are built to “break safely”.

•By now you are probably asking yourself…if Y2 capacitors are so great and can be used for X2 purposes … why not just forget about X2 capacitors and use Y2 type all the time? There are two good reasons … cost and size. Y2 safety capacitors are more expensive than X2 type and Y2 capacitors are larger (which can may make installation harder). Using Y2 type capacitors when an X2 type is all that is required would be like re-capping your tube radios with 1600 volt capacitors rather than 630V caps. All you have done is spent more money that you had to.

•Once in a while you will see a safety capacitor that is a combination of X and Y classes. For example, an X1/Y2 ceramic disc safety capacitors. This simply means that the capacitor meets safety qualifications as both an X1 capacitor and an Y2 capacitor. If I might use a car analogy again, you might think of an X2 capacitor as a special summer tire, an Y2 as a rugged winter tire and an X1/Y2 as a versatile all-season tire.

Construction of Safety Capacitors:

•Safety capacitors are available in ceramic disc and metalized film or paper. The film type are made of self-healing metalized polyester, polypropylene or paper and usually come in a “box” style casing as the capacitor is encased is a flame retardant or flame-proof case.

•Ceramic disc safety capacitors have the advantage of being economically priced and compact in size (making installation easy). One limitation ceramic disc safety caps have is that the largest uF capacitance size available is 0.01 uF (which is sometimes lower than what is needed per the schematic). If you require Y2 safety capacitor that has a capacitance over 0.01uF you will need to use Y2 capacitor made of Poly Film.

•Type X2 film capacitors are also very economical, are relatively compact and are available in a wide range of sizes.

•Y2 film capacitors are more expensive and larger that both disc capacitors and X2 film capacitors. Most film capacitor manufacturers make Y2 capacitors up to 0.047uF maximum.

•All safety capacitors should have certifier’s symbols on their casing. For example UL (for USA), CSA (for Canada), VDE (for Germany), etc. To ensure you are using properly certified safety capacitors check that certification symbols (see below) are on the cases.

•There are also certain safety standards/certification tests that you want the capacitors to meet. For Radio, TV and certain other telecom use the requirement the standard that should be met is: UL1414 (USA); CSA C22.2 No.1 (Canada) and EN132400 (Europe).

- Previous [Return Home] [Print] [Go Back] Next

Contact Us

Contact Person:

Miss Li MeizhenTel:

86-769-82825339- 82825369

- 18929453899

Fax:

86-769-82829959Email:

nanalee.mc@163.com